New options available and John Suhr’s ideas behind them.

We are always on a never-ending quest of tone, improving how we understand our instruments and giving our customers the choices they want. John Suhr wanted to reach out and share his thoughts to educate and possibly even dispel any misunderstandings and myths about the differences between Quarter Sawn and Flat Sawn maple.

We are happy to announce that we are now offering both Quarter Sawn and Flat Sawn maple as a neck wood options on Custom builds.

Largely this was due to a growing number of customer requests and Internet threads talking about how flat sawn is different in way of stability. Of course, giving our customers the options they want is the very heart of a custom guitar builder like Suhr.

However, the ideas behind these opinions and the differences between Quarter Sawn vs. Flat Sawn are something that John wanted to talk about.

First of all, what do we mean by Quarter Sawn and Flat Sawn?

First of all, what do we mean by Quarter Sawn and Flat Sawn?

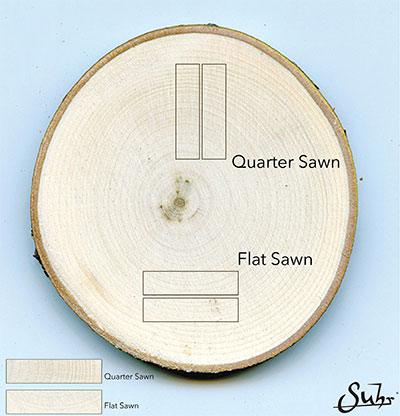

These terms refer to orientation in which a piece of wood is cut from a log of timber. Cutting the neck blanks in a different orientation to the log will result in the neck having a different grain structure. You can see what your guitar has by looking at the top of the headstock. The image at the top of the page shows a Quarter Sawn neck on the left and Flat Sawn neck on the right. In the photo, you can clearly see the direction in which the grain runs. Vertical grain pattern comes from Quarter Sawn maple and the neck on the right has a horizontal grain pattern, which is Flat Sawn.

What does this mean for neck stability and where did the Quarter Sawn vs. Flat Sawn debate all start? Here’s John,

“Maple has diffuse pores in its grain structure, so as far as stability is concerned, it does not have more flex in one direction over another. Most vintage instruments were Flat Sawn, simply because of the availability of wood in the ’50s and ’60s. A byproduct of this is there are plenty of people who feel Flat Sawn sounds better or feels better than Quarter Sawn. There are also people who feel that Quarter Sawn is punchier, and some companies are praised for using straight Quarter Sawn lumber on their necks. My opinion after building guitars for 40 years is there is basically zero difference. Quarter Sawn has a slight advantage in that it is more dimensionally stable in the width direction. However, we dry our wood very carefully so this is not an issue. With roasted maple, none of it matters. Flat Sawn will also show more figuring on the side of the neck if it is for instance flame maple. Some builders exclusively use Flat Sawn, and others only use Quarter Sawn. Since I have no opinion that one is better than the other, we have decided to now offer both options on Custom builds.”

If you are ordering a new Custom instrument and are interested in Flat Sawn maple, please reach out to your favorite Suhr Dealer to learn more about this option and all of the available specifications when designing your Suhr Custom, and we will get to work building your dream guitar.

Thank you all, keep safe, keep healthy, and keep making music!

Quite informative. What are John’s views on:

1. Roasted maple vs regular maple.

2. Stability of figured maple for necks.

Excellent comments by John. I have been involved with wood grain and several species from my 53 building industry years and as an architect also. I will make a comment for your consideration which is totally theoretical since I have not tested this in any way. This has to do with flat vs quarter sawn but in the way of tonality. So, as a plausible launching platform, I’ll draw attention to the growth rings of any significant size piece of lumber. There are alternating hard and soft rings acquired every year throughout the life of the tree which also alternate in thickness and possibly hardness depending on the meteorological conditions from year to year; the moist/cool/wet/dry various combinations over short or long spans. I would postulate that the flat sawn maple neck would distribute an even tonal quality to each string since each growth ring would distribute it’s quality to every string equally across the string platform whereas quarter sawn would possibly be subject to some “very slight” tone variations since there could be growth ring variations lets say towards the sixth string side and a significant difference of those rings toward the 1st string side. It seems that a flat sawn could possibly be a slightly more homogenized distribution to the strings. Realistically, I believe this might be like splitting hairs with an electron microscope to find an answer, but, if anybody would know the answer, I believe it would be you, John. Thanks for your time to consider this in the context of flat vs quarter sawn.